Sheet Metal Forming

Our sheet metal processing is versatile and highly flexible. The systems are designed for the repetitive production of components in batch sizes from small series of ten pieces to production batches of 100,000 pieces.

We achieve maximum flexibility and productivity with our Trumatic laser-punching machines, equipped with 4000-watt lasers and an automated sheet metal storage system. These machines allow for laser cutting, punching, forming, and thread tapping of parts with material thicknesses ranging from 0.5 to 8 mm. The Active Die enables scratch-free processing, expands the range of forming options, and prevents snagging during downward forming operations.

The largest of our six CNC press brakes offers a bending length of up to 3 meters and a pressing force of 200 tons.

A newly added robotic bending cell with 120 tons of pressing force and a bending length of 2 meters enables automated bending and loading

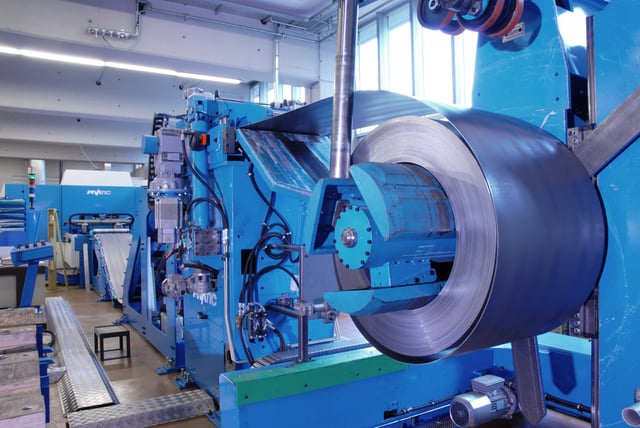

On our PIVATIC CNC stamping line we stamp parts from strips (coils) ranging from 50 to 600mm in width and 0.5 to 4mm in thickness. We adjust the material width optimally to the part, thus minimizing material usage and processing time.

We produce large quantities of stamped and formed parts with thicknesses from 0.5 to 8mm on the two automatic stamping machines with a press force of 100 and 250 tons in progressive dies.